We help create high productivity using modern pneumatic conveying solutions

Heavy lifting and dusty workplaces are now a thing of the past

Description:

The conveying of bulk materials in the production process can now be automated in virtually all cases. A number of pneumatic transport systems are now available for use according to the respective bulk material, the nature of the task and the available space. In principle, pneumatic transport systems are differentiated into underpressure and overpressure. A combination of these systems is also possible. Powders, granules and many other dry bulk materials can be transferred through closed pipelines using a pressure differential. Pneumatic conveying systems are designed to use this pressure difference to move bulk materials from one process area to another cost-effectively in the food and beverage, pharmaceutical and chemical industries. How does the pneumatic conveyor work? Pneumatic conveyors either work with positive pressure when bulk materials are blown by the equipment from one point to another. Vacuum conveyors on the other hand are pneumatic conveyors that work with vacuum. These systems consist of four basic elements: a vacuum source, a material feeding device, a conveying line and a filter-system.

an air filter system

Low-pressur Vacuum conveying

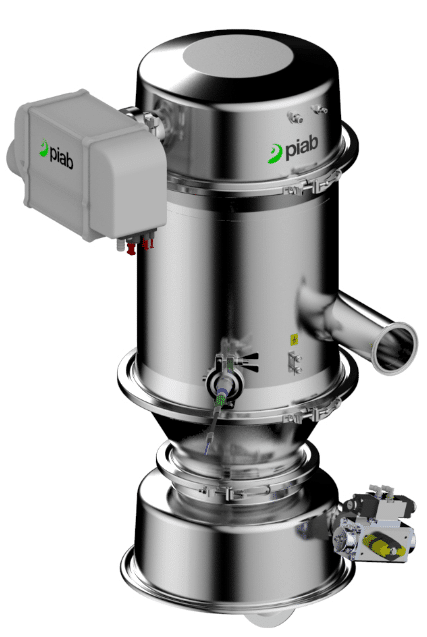

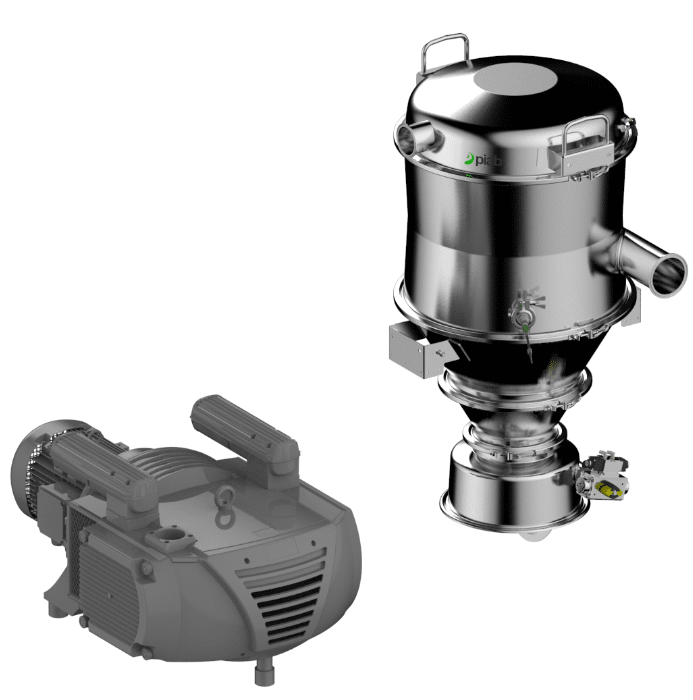

Vacuum conveying systems offer clear advantages when conveying products from multiple infeed points to a single discharge location. Product channeling is extremely simple and dust-free due to the absence of overpressure. Bulk material is conveyed from one infeed point at a time through pipes or hoses to a vacuum conveyor. The vacuum suction stops, and the bulk material is now collected in the vacuum conveyor. The bottom hatch of the vacuum conveyor opens, and a filter blast is activated to clean the built-in filters. The bulk material falls out through the fully open bottom hatch and into the customer's receiving container, which can be a mixer/blender, sifter, sack, or packaging machine. PIAB system is dustproof and is a simple and safe process.

Positive Pressure Conveying

Pneumatic conveying (positive pressure conveying) is ideal for transporting products from a central source to multiple destinations over extended distances. Because the product is conveyed against the resistance of air, additional safety valves and pressure vessels are necessary to ensure safe and efficient operation.

Dilute-phase or Dense-phase

The selection between dilute-phase (10-30% vacuum) and dense-phase conveying (40-70% vacuum) depends on the properties of the bulk material being conveyed and the specific requirements of the application. Dilute-phase transport is typically used for materials that are easily fluidized and have good flow characteristics. Dense-phase transport is more suitable for materials that are difficult to fluidize or are abrasive. We offer a range of pneumatic conveying systems that can be tailored to meet the specific needs of each application. In many cases, semi-dense phase transport, which is a combination of dilute-phase and dense-phase transport, is the most effective solution.