PIAB industrial vacuum conveyors

Efficient and simple pneumatic vacuum powder conveyors from PIAB

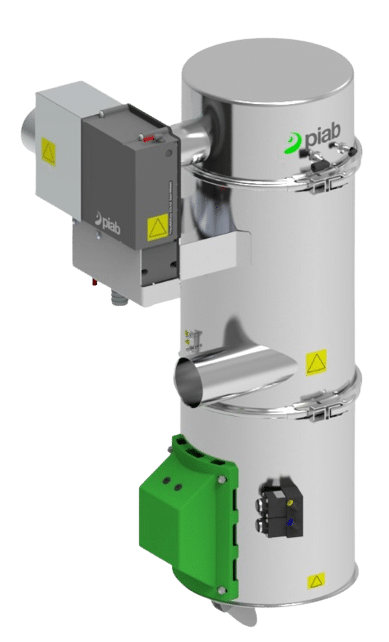

PIAB piFLOW® Industry 200

Vacuum conveyor in rolled 304 stainless steel. Capacity up to 1.5 tonnes/hour.

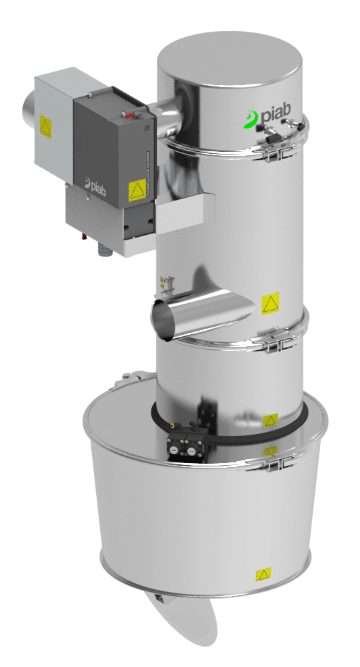

PIAB piFLOW® industry 600

Vacuum conveyor in rolled 304 stainless steel. Capacity up to 4 tonnes/hour.

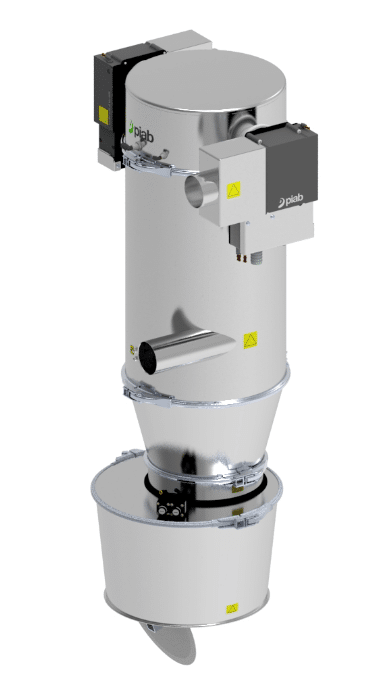

PIAB piFLOW® industry 800

Vacuum conveyor in rolled 304 stainless steel. Capacity up to 7.0 tonnes/hour.

piFLOW®i - Compact and powerful vacuum conveyor for industrial use

piFLOW®i is a versatile and efficient vacuum conveyorthat is particularly suitable for General industry and selected applications in chemical production. With its High capacity of up to 7.5 tonnes per hour and compact design piFLOW®i is an ideal choice where space is limited and demands are placed on Efficient and dust-free material handling.

The conveyor is often used as a Energy-efficient alternative to mechanical conveyorsespecially in environments with a need for Minimal maintenance and high reliability.

Key benefits of piFLOW®i:

Dust-free and hygienic transport of powder and granules

COAX® technology - The most energy-efficient vacuum solution on the market

Low footprint - perfect for Space-restricted installations

High capacity - up to 7.5 tonnes/hour

Available with both ejector driven vacuum pump or mechanical pump

Ideal for automating and upgrading existing systems

piFLOW®i contributes to a Clean and safe production environment and makes it possible to optimise the flow of your production - without compromising on performance or flexibility.

Easy installation and high capacity with piFLOW®INDUSTRI vacuum conveyor from PIAB

piFLOW®INDUSTRY from PIAB is a robust and user-friendly vacuum conveyordesigned with a focus on Efficient powder handling and fast installation. With an innovative construction that includes a Fully open bottom hatch, ensure a Fast and complete discharge of the material - completely free of cone-shaped or bevelled surfaces where powder can otherwise stick.

This solution not only provides a more Effective cleaningbut also a Faster cycle timewhich means Increased capacity and higher production efficiency.

Advantages of the piFLOW®INDUSTRI vacuum conveyor:

Easy installation - Supplied as complete installation kit with all necessary parts

Made in AISI 304 stainless steel - Long service life and hygienic operation

Fully open bottom hatch - No product build-up, easy cleaning

Increased cycle speed - gives higher Throughput and capacity

Comes with Manual in Danish, Swedish, German or English

With piFLOW®INDUSTRI you get a Reliable and efficient vacuum conveyorEasy to install and integrate into existing process lines. Perfect for industrial organisations that want a Dust-free, fast and reliable powder transport solution.

piFLOW®i - Robust and dust-free vacuum conveyor for industrial material handling

When there is a need for a Reliable, robust and versatile solution for the transport of demanding industrial materials is piFLOW®i vacuum conveyor from PIAB the obvious choice. This vacuum conveyor is designed to handle a wide range of Powder, granules and bulk goods with high efficiency and minimal maintenance.

Typical materials that can be easily and safely transported with piFLOW®i include Detergents, desiccants, sand, industrial salt, toner powder, clay, chromium oxide, aluminium oxide, talc, silica, cigarette filters, walnut shells, plastic pellets, PVC powder, calcium carbonate, methyl cellulose and waste - and many more.

piFLOW®i is the intelligent alternative to:

Bucket elevators

Belt conveyors

Screw conveyors

With piFLOW®i you get a Dust-free and ergonomic work solutionthat protects operators from Respiratory risks and exposure to hazardous or allergenic substances. The closed vacuum system prevents spillage while ensuring a Clean and safe production environment.

Benefits of piFLOW®i:

Efficient transport of a wide range of industrial and chemical materials

Dust-free operation - Significantly improves the working environment

Ideal for materials that are toxic, harmful or abrasive

High capacity in a compact and modular design

Low maintenance and easy integration into existing systems

Increase your reliability and protect your staff and production environment with a piFLOW®i vacuum conveyor from PIAB

Martin's extensive experience, which covers roles from project manager to production coordinator at recognized companies such as Labotek A/S, Lesjöfors AB, Sandvik Coromant and Sandvik Materials Technology, underlines his broad professional competence. His expertise in leading projects, optimizing processes and driving growth within each organization enriches Provak with a unique and valuable perspective.

In his previous position as sales engineer and product manager, Martin has had a key position in designing and specifying technical solutions, with an in-depth understanding of automation through the use of vacuum conveyors, vacuum technology, mechanical engineering and the implementation of Lean processes. This background contributes significantly to Provak by ensuring an integrated approach to addressing and solving complex industrial challenges.

Through Martin's leadership and technical insight, Provak is strongly equipped to meet the challenges of the future with innovative solutions that not only optimize processes, but also contribute to sustainable growth and efficiency for our B2B clients.