PIAB premium vacuum conveyors

High-quality, ATEX-certified, high-performance pneumatic powder vacuum conveyors from PIAB

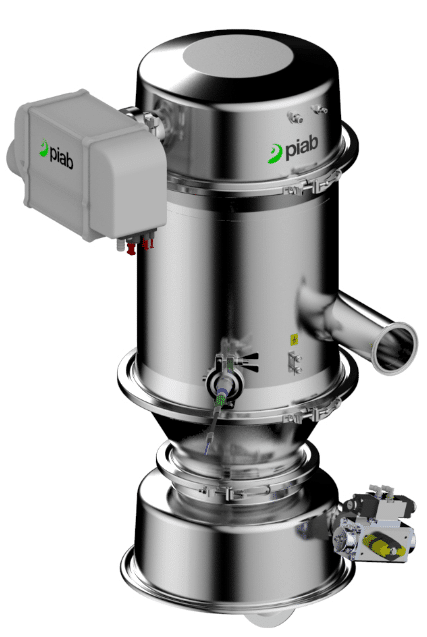

PIAB piFLOW® premium 400

Vacuum conveyor in stainless steel ASTM 316L, RA 0.4. Capacity up to 4.5 tonnes/hour.

PIAB piFLOW® premium 800

Vacuum conveyor in stainless steel ASTM 316L RA 0.4. Capacity up to 7.0 tonnes/hour.

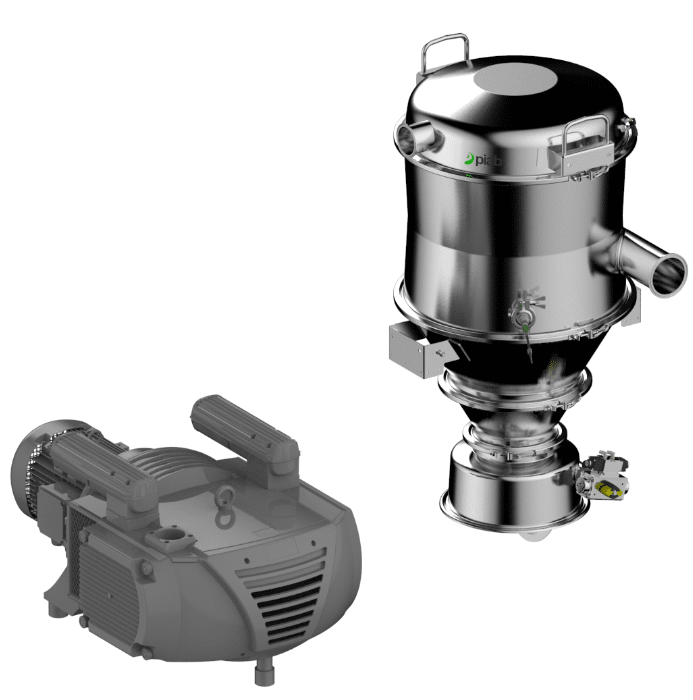

PIAB piFLOW® premium 1200

Vacuum conveyor in ASTM stainless steel 316L. Mechanical pump. Capacity up to 12 tonnes/h.

Stringent reliability requirements? Choose piFLOW®PREMIUM vacuum conveyor from Piab

When it comes to Reliable and hygienic transport of powders and ingredients, er piFLOW®PREMIUM vacuum conveyor from Piab the obvious choice. This conveyor is designed specifically for industries with Extra high demands on quality, safety and reliability - including the food industry, the pharmaceutical sector and the chemical industry.

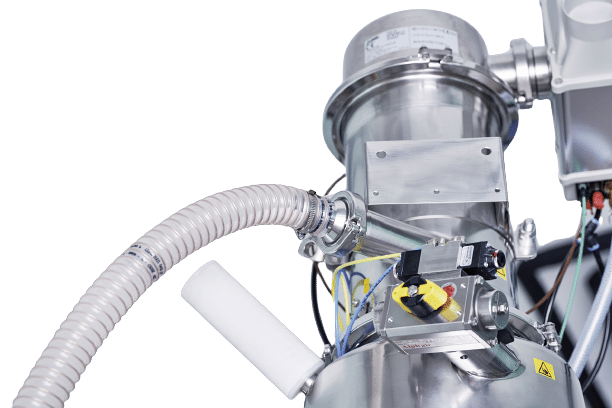

piFLOW®PREMIUM is made of stainless, acid-proof 316 polished steelwhich ensures a long lifespan and easy cleaning. It fulfils the strictest standards for Process optimisation and hygieneand gives you a Efficient, contamination-free and reliable powder handling for many years to come.

With piFLOW®PREMIUM you get:

Maximum reliability - Reduce downtime and production stoppages

Documented hygienic design - Ideal for sensitive products

Durable construction in acid-resistant stainless steel (316L)

Efficient and Gentle transport of powders and granules

If you are looking for a premium vacuum conveyorthat match the demands of modern production are piFLOW®PREMIUM from Piab The safe option.

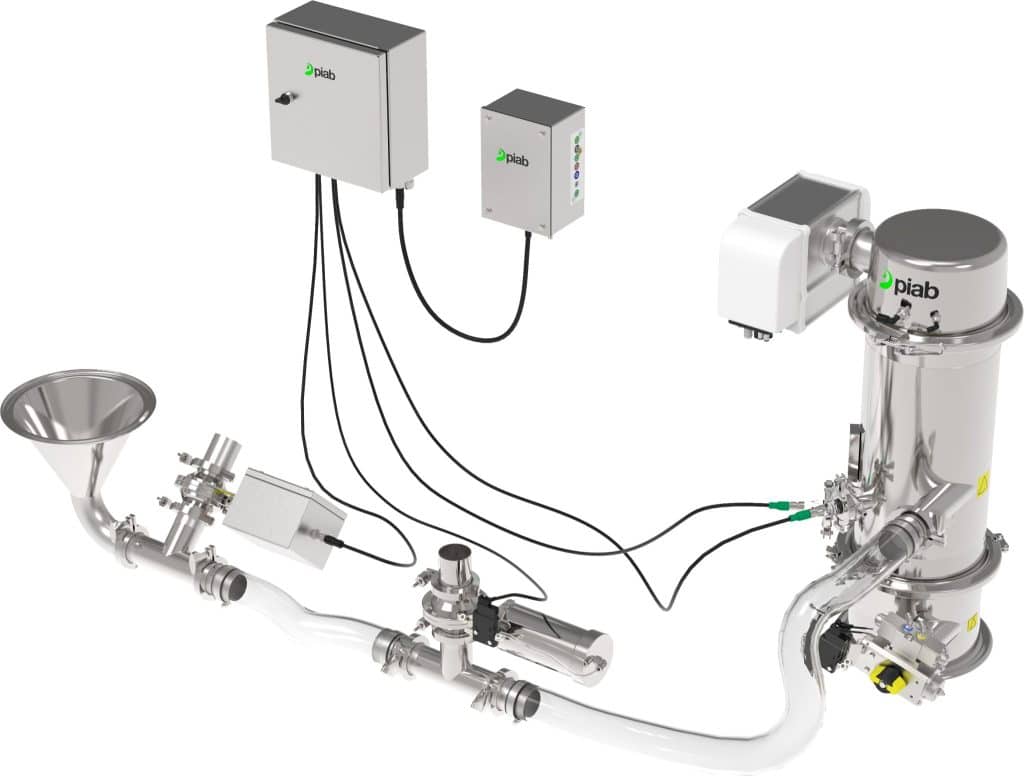

Efficient powder handling automation with PIAB piFLOW® Premium vacuum conveyors

Automation with PIAB's vacuum conveyors makes it easy and efficient to handle even the most challenging powder types. piFLOW® Premium from PIAB is an advanced range of modular vacuum conveyorsthat can be customised precisely to your production - whether it's fine powder, high capacity or Handling hazardous materials.

With piFLOW® Premium vacuum transport you get a flexible and reliable solution for Transport bulk goods, pigments, small components and powders - all under controlled vacuum conditions. The system can work in both dilute phase and dense phasedepending on the material and your specific requirements.

Benefits of piFLOW® Premium:

Efficient and Gentle transport of even complex and challenging materials

Easy installation and operation - Minimise downtime and optimise operations

Contributes to a Clean and safe production environment

Reduces waste and improves the production economy

Made in Hygienic, 316L stainless steel - Ideal for food, pharma and chemical sectors

Provak and PIAB are ready to help you optimise your Powder handling with automated vacuum conveying. Whatever your industry or challenge, we'll find the right solution for your production.

Safe and efficient hump transport between process steps in pharmaceutical production

I pharmaceutical production is Powder transport between process steps a critical part of the manufacturing process. Here, manual handling can lead to challenges such as Health risks for staff, contamination, material separation and product waste - at the same time as the requirements for documentation, quality and compliance are strict.

With our Automated and safe vacuum transport solutions you get a closed systemthat protects both staff and product. Our solutions are tailored to your needs and ensure a Continuous and controlled flow of powder materials from one process step to the next - without any open transfers.

Benefits of automated powder transport between process steps:

Closed and hygienic system - Minimises contamination risk

Increased Safety and ergonomics for operators

Reduce Product waste and material loss

Complies with applicable GMP and quality standards

Flexible solutions customised for both New and existing production lines

We offer Intelligently designed transport solutionsthat effectively Connect your process steps from start to finish - with a focus on safety, reliability and proven quality.

Contact us today for a solution that optimises your process flow and protects your product.

Martin's extensive experience, which covers roles from project manager to production coordinator at recognized companies such as Labotek A/S, Lesjöfors AB, Sandvik Coromant and Sandvik Materials Technology, underlines his broad professional competence. His expertise in leading projects, optimizing processes and driving growth within each organization enriches Provak with a unique and valuable perspective.

In his previous position as sales engineer and product manager, Martin has had a key position in designing and specifying technical solutions, with an in-depth understanding of automation through the use of vacuum conveyors, vacuum technology, mechanical engineering and the implementation of Lean processes. This background contributes significantly to Provak by ensuring an integrated approach to addressing and solving complex industrial challenges.

Through Martin's leadership and technical insight, Provak is strongly equipped to meet the challenges of the future with innovative solutions that not only optimize processes, but also contribute to sustainable growth and efficiency for our B2B clients.