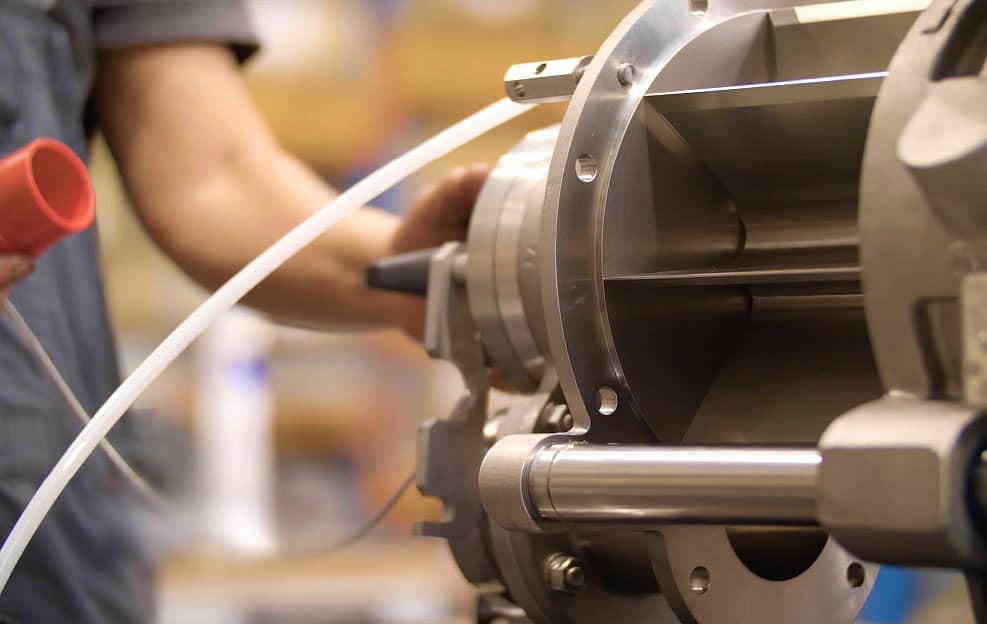

Rotary Valves

Optimizing product flow in pipe conveying. Our Rotary valves have a well-established reputation for handling powder and granular products from all industries, such as dairy, food, pharmaceutical, plastics and chemical.

Rotary valves optimize powder processes:

- Optimized control of product flow to predetermined capacity in our vacuum transport systems.

- Maintenance of pressure difference between processes, e.g. in our vacuum transport systems.

- Explosion barrier for safety protection.

- Flame barrier for proactive management of flames.

- Isolation of processes, e.g. in spray tower, for optimum efficiency.

Rotary valves food

Coperion FXL (full access) extraction devices for cell locks have been developed especially for applications with strict hygienic requirements in food production. These systems provide free, unhindered access to the Rotary valves inner rotor blades for quick and easy cleaning or inspection. The newly developed FXL system is equipped with side-mounted linear guide rods that allow the rotor to be pulled out of the housing with great ease and then reinstalled precisely without obstructing access to the housing interior. By using a hinge, the extended rotor can be swung to the side in various positions and pushed back along the blade. With these individual options, both the inner housing as well as the rotatable rotor itself can be optimally cleaned, even in conditions where space is tight.

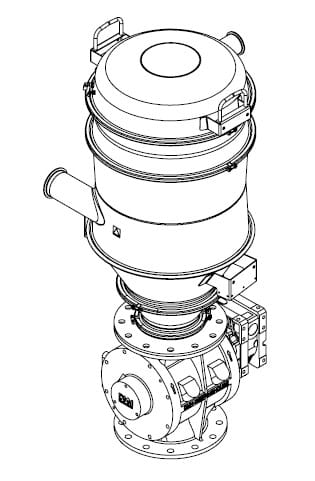

Rotary valves ZRD

Shown here is a Coperions ZRD Hygienic Rotary Valve. This cell lock is designed for sanitary, pharmaceutical, food and chemical applications where contamination is a problem and frequent cleaning is required.

Rotary valves unique sanitary

Cell lock FXS off Coperion in a unique sanitary product design. Operational reliability and durability.

Easy to clean: Fast, efficient cleaning and inspection due to optimal accessibility.

Certified CIP versions (Cleaning in place)

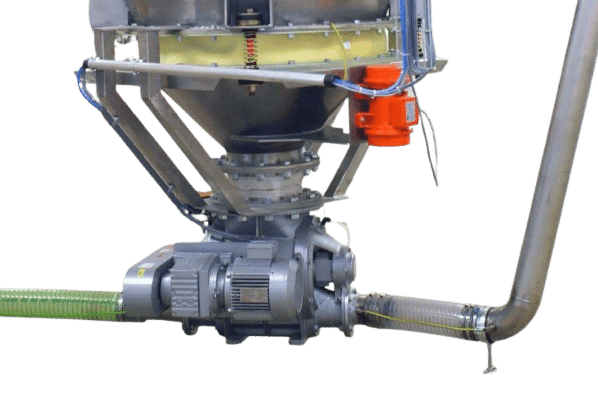

Vacuum conveyor with Rotary valves

We make customized solutions with PIAB vacuum conveyors and Rotary valves. By building together, it is possible to create unique pneumatic transport systems. In this way, we can ensure greater capacity by enabling continuous pneumatic vacuum conveying. We can increase the vertical conveying length by 3 times. Call and find out more.

Martin's extensive experience, which covers roles from project manager to production coordinator at recognized companies such as Labotek A/S, Lesjöfors AB, Sandvik Coromant and Sandvik Materials Technology, underlines his broad professional competence. His expertise in leading projects, optimizing processes and driving growth within each organization enriches Provak with a unique and valuable perspective.

In his previous position as sales engineer and product manager, Martin has had a key position in designing and specifying technical solutions, with an in-depth understanding of automation through the use of vacuum conveyors, vacuum technology, mechanical engineering and the implementation of Lean processes. This background contributes significantly to Provak by ensuring an integrated approach to addressing and solving complex industrial challenges.

Through Martin's leadership and technical insight, Provak is strongly equipped to meet the challenges of the future with innovative solutions that not only optimize processes, but also contribute to sustainable growth and efficiency for our B2B clients.