Customer service

- We are ready to help you:

- (+45) 29 60 90 04

- info@provak.dk

- Book a customer visit

- CVR/VAT - no. DK43026704

At PIAB, we are dedicated to providing unique and customised solutions that meet your specific needs. Our starting point is our extensive range of standard equipment from renowned manufacturer PIAB. These products form the basis of our customised solutions, and we work hand in hand with our customers to fine-tune and adapt the equipment for each job. With our expertise and experience, no challenge is too big or too complex.

But we don't stop there. We also have expertise in creating custom-designed equipment to meet the most unique and demanding applications. Our skilled team of engineers and technicians are ready to take on the challenge and develop customised solutions that fit your business needs perfectly.

Our history speaks for itself. We have a long and proud history of providing reliable vacuum transport solutions to a wide range of industries. Our extensive network of factories and specialists enables us to maintain the highest standards and ensure the quality of our products and services. When you choose us as your partner, you can rely on us to deliver safe and reliable solutions that meet the highest standards. We look forward to working with you to find the perfect vacuum transport solution that will benefit your business.

Many of our tasks involve filling a container/tank, mixer or mixer. In this case, it is a receiving container that stands on weighing cells, so that there is control over how much powder is dosed into a mixer below floor level.

The vacuum pump is a mechanical pump which is placed in another room. The PIAB vacuum conveyor is a piFLOW premium, which is manufactured in stainless 316L. Automatic filter cleaning built-in. Pneumatic steering mounted.

Solution: Hygienic design, with vacuum transport.

Approvals: FDA, EC No 1935/2004 and EC No 10/2011. ATEX dust, zone 20 & 22 certified.

You often encounter powder materials, which make extra demands on equipment. Here is the extra fine & difficult powder material that gets stuck in the filter and means that the customer often has to change and clean the filter. We create a solution where we use our standard equipment, but create a design where we share the receiver-container and filter. A good solution that still keeps the equipment simple and standard. The customer is very satisfied and they have not changed the filter since.

Solution: Dust-free Vacuum transport with almost no maintenance.

Approvals: ATEX dust certified.

When powder needs to be filled into a packaging machine, there are many mechanical conveying solutions that can handle the task, such as screw conveyors or bucket elevators. However, it requires a lot of space in the factory and is an expensive solution. Here, vacuum transport is a big advantage, as it does not require extra space in the factory, and we can easily automate the filling of the powder. A level sensor registers and activates our control, which starts the vacuum transport. In this way, filling the 100% becomes automatic. We can do it hygienically, safely in Atex areas. easy to maintain and clean.

Solution: Hygienic, Automatic, Small footprint.

Approvals: FDA, EC No 1935/2004 and EC No 10/2011. ATEX dust, zone 21 certified.

We are happy to offer tests at our laboratory, where we ensure that we can meet the requirements. Here, two identical vacuum transport systems have been delivered, which ensure a large capacity without damaging the product, which in this case was corn seed. As we are talking about greater capacity over long distances, and that the equipment must be in operation 12 hours a day, we offer mechanical vacuum pumps located just below our vacuum conveyors (see picture). Vacuum valves control on/off for vacuum. Our mechanical vacuum pumps are oil-free vane pumps of very high quality, as there are always requirements for operational reliability on our solutions.

Solution: Safety / functionality / gentle vacuum transport.

Approvals: Declarations of Conformity

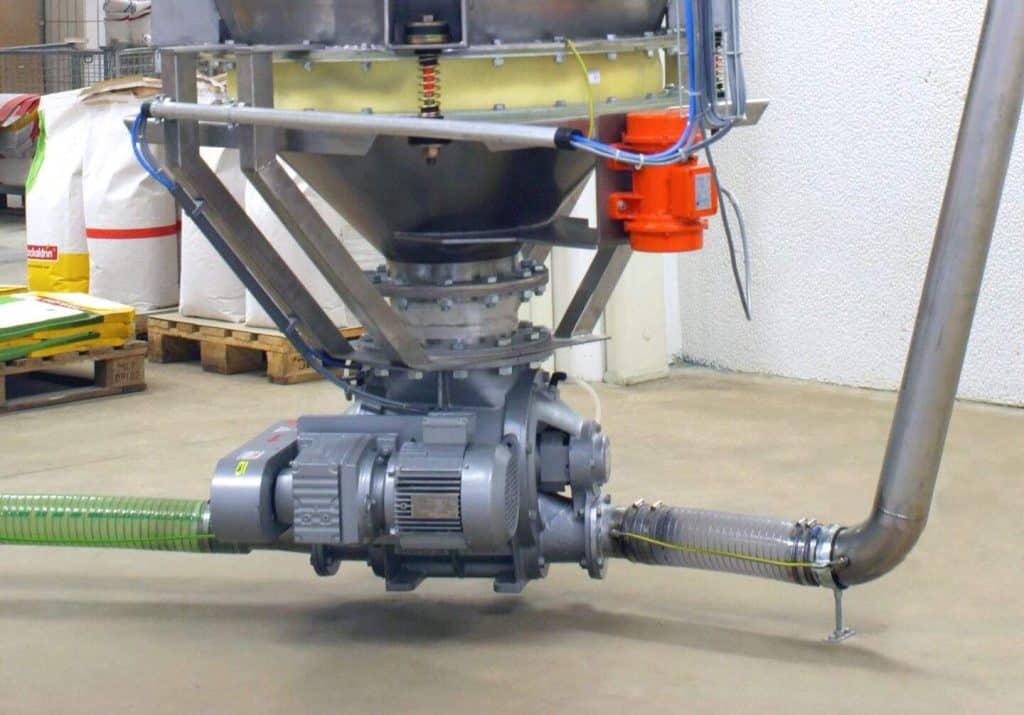

The first thing that is important to decide on is how the suction point should be designed. We offer a range of standard equipment to ensure a reliable suction point. We have several versions of feed adapter with adjustable carrier air, we have several suction lances, cone outlets and shown here in the picture we have cell locks that can be mounted under silos or tanks. We can also use cell locks under our PIAB vacuum conveyor, so we have a continuous dosage.

Solution: Reliable pneumatic conveying

Approvals: FDA, EC No 1935/2004 and ATEX dust certified.

There are often tasks on powder that must be handled from bags. There can be paper bags or plastic bags. We offer several bag surcharges, which are a safe way to have as a Feedpoint. Our standard bag top fits our vacuum conveyors perfectly.

Solution: Hygienic design. Security.

Approvals: EC No 1935/2004 and EC No 10/2011.